PCB manufacturing process involves several steps. Everything first starts with an idea. You need to first be clear with your idea and what you want to achieve. Once you have a clear understanding of what you want your equipment to do, you need to design the PCB you can send it to PCB designing companies or to PCB manufacturing companies that take care of everything and not just PCB designing.

Once you have the PCB design by the design engineers, it has to be printed in the boards to create the prototype. Without prototype, it is not normally taken to large scale production. Using the prototype all the functionalities of the device are tested and the issues are corrected. Only when the fully functional prototype is ready, PCB mass production is carried out.

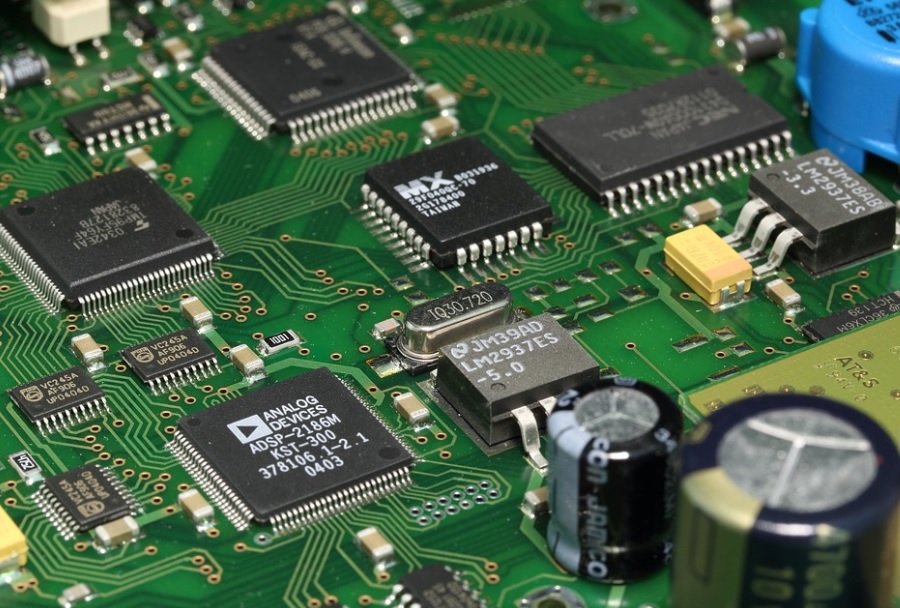

Various components are involved in the printed circuit boards such as the resistors, capacitors, IC or integrated circuits, fuses, and so on. When you go for mass production, these components have to be sourced. The overall functionality, stability and the quality of the PCB is dependent on the quality of the components used. PCB components sourcing is therefore a major step. The PCB manufacturing company is normally responsible for PCB components sourcing too. You need to make certain that your manufacturer keeps to the highest standards when sourcing the PCB components.

The next step is PCB assembly and this again happens to be a very crucial step in the PCB manufacturing process. The assembly has to be handled in a lead free environment to be in compliance if you are planning to export your electronic equipment to other countries that require PCBs to be manufactured in a lead free environment.

The PCBs manufactured need to be tested by the manufacturer to ensure that they are working perfectly without any flaws before they are shipped to the customer. Untested PCBs should not be accepted because it could affect the quality of your product and its functionality.

As you see that PCB manufacturing is an elaborate process. It needs to be handled correctly at every step of the way, failing which you will not be able to confidently market your electronic products. Find the most trustworthy manufacturer of PCBs and get the best quotes from the manufacturer. Try to get multiple quotes so that you know you are paying the right price for your PCB manufacturing needs. At the same time, never compromise on the overall quality just because you are getting lower quotes as it would affect your brand reputation.

Before finalizing your PCB manufacturer, you need to make certain that they are capable of delivering you orders in a timely fashion without compromising on the quality of the PCBs.